that enhance children’s environments

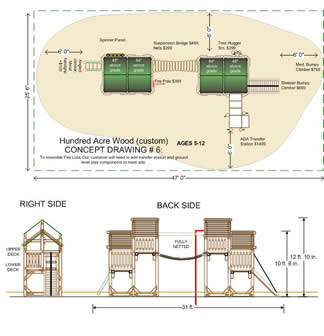

Built exclusively by the Playground Crew at Bears, our natural playgrounds are constructed primarily from cedar logs and are perhaps the best looking systems in the universe. Create your own design, pick one of ours, or we’re happy to create a design tailored to you for free!

LuckyDreams ist ein Online-Casino, das sich auf die besten und verrücktesten Pokies konzentriert. Obwohl es erst im Jahr 2021 gegründet wurde, hat sich dieses Casino zu einem beliebten Betreiber entwickelt und hat bereits viele Stammspieler.

Das Lucky Dreams Casino bietet einen riesigen Willkommensbonus, wertvolle Werbeaktionen und verfügt über eine umfangreiche Bibliothek mit den neuesten Online-Pokies. Viele australische Spieler kennen diesen heißen Igaming-Spot bereits, aber für diejenigen, die noch nicht damit vertraut sind, hier sind unsere Einblicke.

Wie bereits erwähnt, ist LuckyDreams ein absolut neuer Spieler im Bereich der Online-Casinos und bietet noch nicht allzu viele verschiedene Boni und Promotionen an.

Neue Spieler werden mit dem Willkommensbonuspaket belohnt, das aus 4 verschiedenen Boni besteht, die nach den ersten 4 Einzahlungen gewährt werden. Für regelmäßige Spieler gibt es drei wöchentliche Boni, die jeden Dienstag, Freitag und Sonntag vergeben werden, sowie einen Reload-Bonus. Lassen Sie sich von dieser kurzen Liste nicht täuschen, denn die Werte dieser Promotionen sind beeindruckend.

Das LuckyDreams-Casino wirbt für ein lustiges Leben und gute Laune, daher ist sein VIP-Programm mit Bildern von Luxusreisen versehen. Ein Privatjet, türkisfarbenes Wasser, goldene Sandstrände, teure Wolkenkratzer und die berühmtesten Casinos… klingt das nicht nach VIP? Aber sicher doch!

Das VIP-Programm von LuckyDreams besteht aus bis zu 7 Stufen, die nach den Städten benannt sind, in denen sich berühmte Casinos befinden (Atlantic City, Sun City, Melbourne, Venedig, Macao, Monte Carlo und Las Vegas). Die Online-Casinospieler müssen Einsätze an den Pokies machen und Treuepunkte sammeln. Je mehr sie spielen, desto mehr Punkte erhalten sie, und so können die Spieler in verschiedene Stufen aufsteigen.

check out these cool projects!

who love creating joy for children across the world

We are so lucky to have an amazing team that loves to create joy for children across the world! Check out out team members and see if you can find the designer you worked with or the crew that built your playground!

Ozwin Casino is a popular online casino designed for players in Australia. https://ozwincasino.gg/ offers a diverse range of games, including pokies, table games, and live dealer games from top providers such as Real Time Gaming and Visionary iGaming. The casino is licensed and regulated by the government of Curacao, ensuring safe and secure gaming for players. Ozwin Casino offers a variety of payment methods, including Visa, Mastercard, Neosurf, and Bitcoin, with fast and reliable payouts. The website has a user-friendly design with a magical theme, and the customer support team is available 24/7 to assist players with any questions or concerns.

Better yet, come see us in person! Our favorite part of the day is walking though our shop and showing everyone how things are made!

Copyright © 2022 Bears Management Group, Inc. – All Rights Reserved.

Designed and Developed By Noticestry LLC

Notifications